R.C.C. Degradation

Effect of electrochemical activity of dissimilar metal ions present in water and mineral aggregates as electrolytes

The tests which are discussed here very common that is known to all engineers as the basic chemistry.

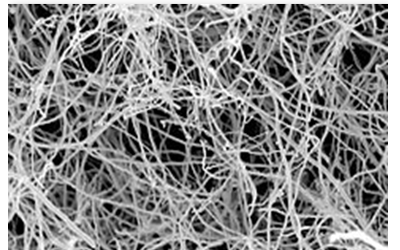

Chloride is known as a steel corrosive ion in R.C.C. As per code of practice the chloride content is measured in construction chemical like admixtures, integral waterproofing additive and polymer emulsions. Any concrete additive is strictly limited within permissible Chloride content limit in all standards as the corrosion generally results from electro chemical cells within the concrete. An electrolyte, usually a solution of salt and water in the concrete, is necessary to form the cells. Oxygen is also necessary for the corrosion reaction to take place. There are many evidences of steel corrosion of R.C.C. due to presence of chloride ions.

But, there are other metal ions which causes degradation of concrete. In this article of Technology Coordination Technology, I would like to focus the effect of those metal ions as electrolyte. I also would like to explain the determination process of those metal ions present in water used in construction industry.

Dissimilar Metal Corrosion – When two different metals, such as aluminium and steel, are in contact within concrete, corrosion can occur because each metal has a unique electrochemical potential. A familiar type of dissimilar metal corrosion occurs in an ordinary flashlight battery. The zinc case and carbon rod are the two metals, and the moist paste acts as the electrolyte. When the carbon and zinc are connected by a wire, current flows.

In reinforced concrete, dissimilar metal corrosion can occur in balconies where embedded aluminium railings are in contact with the reinforcing steel. In this article I will emphasize on determination of dissimilar metals present in water and mineral aggregates which is used in construction like copper,lead, zinc, magnesium as an active electrolyte.

|

|

The presence of above metals in water should be determined by chemical analysis in any laboratory.

Detection and Determination of Metals in Water

COPPER– Copper is determined colorimetrically as copper ferrocyanide or by the diethyldithiocarbamate method.

I would like to describe three methods with an increasing degree of sensitivity.

- AMMONIA METHOD– The ammonium ion reacts with the cupric ion to produce the complex ion ⌠ Cu (NH3)4⌡+ + which has an intense blue colour. This is very sensitive to changes in temperature and to the presence of other ions. For example, the colour obtained by adding ammonia to a solution of cupric chloride is quite different from that given by an equivalent of cupric nitrate. It is therefore safer to convert the copper to sulphate and to use copper sulphate as the standard. The quantity of copper taken should be such that the final solutions contain about 0.012 gm. Per litre, i.e. for the standard, take 10 ml. of a solution containing 0.12 gm. Per litre for a final volume of 100 ml. Ammonia should be added to both the solutions until the blue colour is fully developed. Further dilution should be within 3 N. ammonia (concentrated ammonia diluted to five times its volume).

- As Ferrocyanide. When neutral solutions of potassium ferrocyanide and copper are mixed, a brown colour or a chocolate precipitate of cupricferrocyanide Cu2FeC6N6 is formed. If the correct conditions are chosen, 1gm. Of copper in 2500litres of water can be detected by this method.

- Sodium Diethyldithiocarbamate ⌠ N(C2H5) CS2Na⌡. When this reagent is added to an acidic, neutral or alkaline solution of copper, a golden brown colour is produced. The test determines less than 1 part of copper in 100 million parts of water. It is of particular use for determining copper in water: or in solutions from which nearly all the copper has been removed by deposition. The standard solution should contain about 10 milligrams of copper per litre. Such a solution can be made by dissolving0.393gm.of CuSO4, 5H2O in water and diluting to 1 litre. Use a 0.1%aqueous solution of the reagent. This is somewhat unstable, but will keep for several weeks if stored in the dark. If iron is present, oxidise it, add 2 gm. Of citric acid and make the solution alkaline: if zinc is present, make the solution strongly amoniacal. Add this solution to 10 ml. of the reagent solution, dilute to about 50ml. If necessary balance against a standard solution which has been treated in exactly the same way.

- The extraction method may be used when a considerable quantity of ferric iron is present or when the simple method fails to give a satisfactory result, as when other interfering elements are present or when the quantity of copper to be determined is extremely small.

- Add 2 gm. Of citric acid to the sample and to the standard and dilute each to about 40ml. Add 0.880 ammonia diluted with its own volume of water, until the pH values of the solutions are greater than 9.Test this using phenolphthalein on a spot plate. The indicator should turn definitely red. Bring the volume of each solution to 70ml. and add 10ml.of dithiocarbamate reagent. Mix well and then extract at once with at least four successive portions of 2.5ml. of carbon tetrachloride. Transfer the extractions to small tubes and dilute to 20 ml. with carbon tetrachloride. Compare the colours.

LEAD– Lead may be determined colorimetrically as lead sulphide.

The behaviour of a water sample towards lead may be tested as follows: Cut off two strips of lead sheet: scrape one of these so as to expose the bright surface of the metal, and leave the other in its tarnished condition. Immerse the lead strips in separate beakers of the water, and allow them to stand undisturbed for twenty four hours. Then note the appearance of the lead and of the water.

If the surface of the lead has remained unchanged in appearance, and the water is perfectly clear and bright even after it has been shaken, the water has probably not acted upon lead, since a white insoluble basic lead carbonate is usually formed by the action. To make sure whether any solvent action has occurred, however, it is best to remove the lead strips and to test the water colorimetrically.

The Relative Action of Samples of Different Waters on lead may be expressed as follows:

A strip of sheet lead, 1.5cm. wide, is scrapped bright and is cut into lengths of 2.5 cm. ten millilitres of each of the different water samples are introduced into stoppered test tubes, 15 cm. long and 2 cm. in diameter, and a strip of lead is completely immersed in each sample. The lead strips should be free from grease: they must therefore be handled by forceps, not by the fingers. The tubes are shaken to detach any air bubbles from the lead, and are allowed to stand for one, three, seven or fourteen days as required.

The water is poured off from each tube into a glass cyllinder graduated at 100 ml. capacity. The lead is rinsed in the tube by shaking it with about 10 ml. of distilled water and this water is poured into the cyllinder: the lead is removed and is rinsed by the jet of water from a wash bottle to remove any adherent lead compound into the cyllinder. Five millilitres of decinormal acetic acid are poured into the test tube from which the lead strip has been removed, in order to dissolve any lead compound adhering to the glass: this acid is poured into the cyllinder and the test tube itself is finally rinsed out into the cyllinder. The liquid in the cyllinder is stirred until all lead compounds are dissolved and the liquid is quite clear: it is made up to the 100 ml. mark with water and the lead is determined colorimetrically by the sulphide process.

ZINC– Prepare a standard zinc solution, 1 ml. of which corresponds with 0.1 milligram of zinc, by dissolving 0.44 gm. .of crystalline zinc sulphate in 1 litre of water. Add 2 ml. of 3 N.H2SO4 and 1 ml. of 0.5 N. K4Fe(CN)6 to 50 ml. of the water sample and match the turbidity caused by the precipitation of the zinc ferrocyanide with a sample similarly prepared by mixing 50 ml. of distilled water with a known quantity of the standard zinc solution and with the above quantities of H2SO4 and K4Fe(CN)6 solutions. It is not advisable to add the zinc solution after the ferrocyanide or to use more than 1.5 ml. of the zinc solution. The tubes must be allowed to stand in the dark for five minutes before an attempt is made to match the turbidity.

When much iron is present in the water, it must be precipitated by adding NH4Cl and NH4OH , boiling and filtering before determining the zinc.

Our analytical discussion covered three metal ions as electrolyte solution which has impact on R.C.C. structure. When two dissimilar metal ions are present, electrons flow externally through the circuit from the anode to the cathode because of a difference in potential energy between the two electrodes in the electrochemical cell, which results in the corrosive degradation. The root cause of this type of degradation is quality of water or mineral aggregates, which sometime are contaminated with different metal in form of metal salt. This causes galvanic corrosion. If tests can be conducted at site laboratory following the methods as discussed above, the problem is overcome. TO BE CONTINUED……..

0 Comments