SYLOCON® – AN ADVANCED TECHNOLOGY IN CONSTRUCTION CHEMICAL

PREMANKUR BHATTACHARYA

TECHNICAL HEAD

ANN WORLD

The present work entitled SYLOCON® Nano composite is the eighth edition of this standard reference and fully revised. It contains information on the physical and chemical properties and its potential applications. SYLOCON® is a rare composition of different Nano particles. The natural ingredients started production 50 years back. This is a registered trade mark owned by ANN WORLD. A several study and research was conducted on this product since last 25 years. Product is used for plastering and screed concreting to prevent any crack, efflorescence and water ingression. As well as this is found that its reaction between Nano particles and cement produces a mix, which is absolutely rebound loss free on smooth surface? Laboratory tests were conducted maintaining different dosage starting from 250 millilitres up to 1 litter per 50 Kg. cement. The best result is found using one litre in 50 Kg. cement. Along with Nano composite, a specially made fibre is introduced in this product. The study on that is described here.

Polypropylene fibres are chemically inert, thermally stable, strong, and light, have become more attractive in recent years as reinforcements for cement, sand mortar and concrete.

A property, such as tensile strength, shrinkage and water resistance as well as durability of the concrete and plaster mortar is highly improved after the mortar are reinforced by PP fibres.

However, the ordered chemical structure and lack of polar functionalities, as well as surface smoothness of PP fibres shows poor adhesion characteristics in mortar.

The reason is when fibre reaches its best tensile strength, fibres and cement mortar have already separated from each other, and so the poor bonding characteristic is a severe limitation to the effective use of PP fibres. So, surface modification techniques towards enhancing strength between fibres and mortar is developed in SYLOCON® the Nano composite latest modified additive useful in mortar, concrete and putty. The mechanism of fibres is based on plasma treatment. The fibres are divided into two kinds, reactive and non-reactive plasma modification. Hydrogen or inertia gases plasma never reacts with the polymer only transfer the energy to the surface molecules of polymer in case of non-reactive plasma. So, activity is produced to polymer surface which causes interaction and bond is introduced on polymer surface.

This property is closely related with the quartzite thixotropic property of SYLOCON. Once the fibres come in contact with quartzite gel, automatically the intermolecular bond is created. That helps the fibres not to coagulate. That creates a linear chain in the thixotropic Nano composite, which is in the form of a cohesive gel.

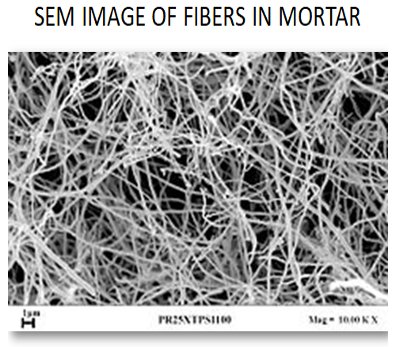

The result is very prominent in its application. As the quartzite Nano particles in thixotropic gel carry the linear chain of the fibres, it attracts cement mortar in such a way that well dispersion of Nano particles and fibres produces a homogeneous mortar.

FIELD ELECTRON EMISSION SOURCES OF FIBRES- Field electron emission ( also known as field emission (FE) and electron field emission is emission of electrons induced by an electrostatic field. The most commoncontext is field emission from from a solid surface into vacuum. However, field emission can take place from solid or liquid surfaces,into vacuum,air,a fluid or any non-conducting or weakly conducting dielectric.

Reaction with cement mortar- Calcium silicate hydrate (also shown as C-S-H) is a result of the reaction between the silicate phases of Portland cement and water. As quartzite Nano particles start reaction with cement particle, retardation takes place. As a result, the strength is gradually increased. Moisture is entrapped in matrix which helps self-curing of mortar. After hardening of mortar the result shows a hydrophobic property of the mortar. Excellent bond strength is observed when the mortar is applied on any smooth surface like AAC Blocks or smooth concrete surface. Due to slow hydration of mortar no shrinkage crack appears on the finished surface due to controlled heat of hydration. Well dispersion of fibres in the mortar produces a continuous chain link of fibre.

That helps to overcome the crack development.

UNDERSTANDING PROPERTY OF SYLOCON BY X-RAY DIFFRACTION TEST – After the product is added to the cement mortar, ad different pattern is observed. This indicates the growth of the new hydration products in mortar. The crystals developed fill up the capillaries. The following diffractograph shows the new properties developed after hydration. From experimental results, it appears that in presence of SYLOCON some Nano particles are produced, which the products of hydration are. The extremely nano size particles have some favourable characteristics. Those fill up the pores and increase the strength of mortar. The microstructure of interface of cement and aggregate are greatly improved. This hinders the water percolation through cured mortar.

Following Scanning Electron Microscopic Image shows the reaction behaviour of cement –sand

Scanning electron microscopic image of different molecular arrangement of SYLOCON and cement

Common problems to solve using SYLOCON

.

.

.

.

Other than the above problems, de-bonding cracks between smooth surface and plaster, wall putty and smooth surface are overcome using SYLOCON for the specific properties mentioned here.

To be continued—————-

0 Comments