SYLOCON® is the product to overcome the challenges of cracking, efflorescence, water seepage on plaster or putty finished AAC Blocks, Fly ash bricks, Red clay bricks, R.C.C. surface and Screed concrete on mother slab.

AAC falls under aerated concrete, high on suction, very high on shrinkage movement.

1) Should be dry to control shrinkage.

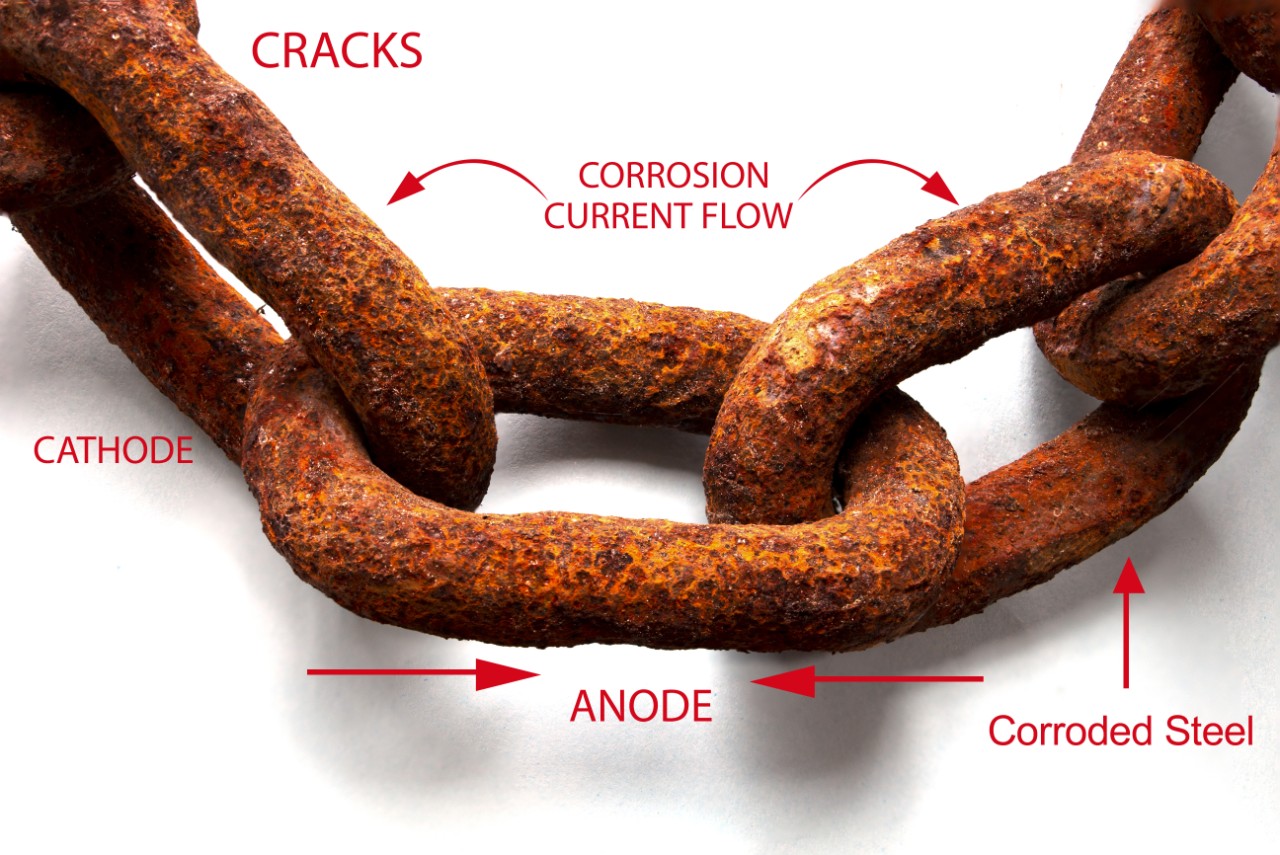

2) Cracks appear mostly at brick joints. Cracks are usually in straight lines or sometimes stepped / diagonal.

AAC blocks are designed to be with low density for economic design of building. Aeration reduces density, by-products being low strength, high water absorption and very high shrinkage. These blocks are produced using aerated cementitious composite, which is autoclaved. Immediately after production, AAC Blocks are usually with high moisture content.

Materials used in AAC blocks, autoclaving process affect shrinkage. For example, if graded aggregates are not up to mark, they will have high shrinkage. AAC blocks should be dried sufficiently before putting them into use. Additionally, no water shall be supplied to AAC blocks during construction. Now, it is common sense that effective water curing affects high cracking in AAC. In that case block fixing agent is used which strength is higher than AAC block, as a result cracks appears at other places. Normal cement sand weak mortar with self curing compound should be used for fixing blocks. Air increases porosity. When pores in the block receive water, they expand. When dried, these pores shrink.

So, AAC expands and contracts. Although very marginal on change in length, brick binding mortar cracks due to tensile stress. While storing at factory/site, blocks are stacked in piles. Blocks in the outer periphery dry out well but the blocks deep inside the pile do not dry enough. Curing is the most important source of expansion. Rain water is another source. Sun is important source of drying. Wind as well, depending on Relative Humidity. Diagonal cracks / cracks through bricks are due to handling of the bricks by labour. AAC blocks are poor in compressive strength; do not resist shocks when dumped from a height. They develop minor fissures internally. Crack propagation is always through the weakest zone. Brick binding mortar will be stronger than the cracked block, so crack goes through the brick. Therefore, we see diagonal cracks Otherwise, cracks in AAC blocks are always in straight lines. Steps may be observed, depending on weaker zones for crack propagation.

Why AAC Blocks Crack?

As the size of block increases, cracking reduces. 4” wide blocks crack higher than 9” wide blocks due to lesser self weight. Change in background is weak zone especially where mesh application is not possible. We see straight line cracks between junctions of columns / beams and walls with no mesh. One or two concrete beds are provided in the walls usually in AAC blocks. If such beds are provided, mesh shall be applied before plastering considering change in background.

If the wall is exposed to wind movement / heavy sun, chances to cracking is high. As the height increases, due to heavy wind cracks may develop. Workmanship For example, cutting the bricks for electrical conduits etc shall be done carefully, without subjecting the blocks to high loads.

Shocks: Due to lack of sufficient self weight, the walls move heavily even with smallest shocks. If nails are used to fix meshes at background changes before plastering, the brick binding cracks.

Packing / filling materials in holes of electrical fittings etc. These also are weak zones, through which cracks appear.

Rain: Always store the blocks in a shade away from rain. Ensure they are dried well before use.

Materials Storage And Brick Binding

Factory Inspection is essential to observe storage conditions. Buy from reliable suppliers who store blocks away from rain. This should be sufficiently dried before supplying to site.

Mesh- Use glass fibre mesh in all junctions. Fibre mesh is flexible and can be easily applied at all junctions even if the column / beam does not flush into the wall. Also apply mesh at the concrete beds.

Use Self curing Mortar by using SYLOCON ® in mortar for both brick binding, putty finishing and plastering.

Precast lintels to avoid curing after application. Store AAC blocks on a dry platform and protected from rain. Make smaller stock piles with enough sun and air to pass through the blocks for drying. Ensure that bricks being used are dry. Moisten surface only to receive mortar.

Carefully select unbroken bricks for brick binding. Any bricks with cracks / defects shall be quarantined for disposal. Apply self curing mortar thoroughly on the full face of the block (not just only at the corners of each side). If the mortar is self curing, thickness does not matter much. However, excess thickness affects the last layer of blocks ending at the concrete slab/beam etc. The opening left for the top most (last) layer could be so small that the mason will be forced to use broken bricks, which results in a weak zone. Due to this, most AAC manufacturers recommend thickness of 3-5 mm for brick binding mortar. Therefore, ensure full blocks are used always.

Best practice is to cast precast lintels and be installed in place. Allow at least 3 weeks of drying of the brick binding before application of plaster. At this stage, some cracks may appear at the joints yielding to shrinkage movement of blocks. Check for cracks to see if any blocks have completely dislodged and can be removed by hand. Remove such loose blocks and scrape the dead mortar in the hole and the block. Check if the block has no damage and can be reused. Apply fresh mortar thoroughly over the face and reinstall the brick using waterproof coating compound. Repeat the process of crack inspection. If due to any reason, half blocks have to be used in the top layers, neatly cut the blocks to required size before application into the wall. Do not use broken bricks.

Ensure water does not reach the blocks in the whole process. Due to uncontrollable reasons like rain etc, if the wall becomes damp, leave it for 2 months of drying. External plaster shall be done only after 2 months of cessation of rains.

Declare the wall is ready to receive plaster if there are no dislodging blocks. Pack all the gaps etc., in the electrical conduits with mortar prepared using SYLOCON ®. Use fibre Mesh of 8” width in all junctions. It is flexible and gets into all the junctions, even if the column / beam do not flush into the wall. Do not use nails to fix the mesh. Mortar may be applied on the mesh, which is self curing.De-bonding between plaster and putty is another important reason behind appearing cracks on finished surface. This is very difficult to control all the above mentioned parameters at site. Ultimate user is mason and workers. System should be mason friendly and complication free.

For more information, visit: https://www.aquacrete.co.in

0 Comments